Epoxy Flooring Cost Factors - What Really Affects Your Final Price

Epoxy flooring is often marketed as a single price per square foot, but in reality, no two epoxy floors cost the same. The final price depends on a combination of surface conditions, material choices, preparation requirements, and how the space will be used.

Understanding these cost factors helps property owners make informed decisions and avoid surprises once a project is underway.

At NES Flooring, epoxy pricing is based on what it actually takes to install a durable, long-lasting system that performs under real conditions across Texas, not a one-size-fits-all number.

Why Epoxy Flooring Prices Vary So Widely

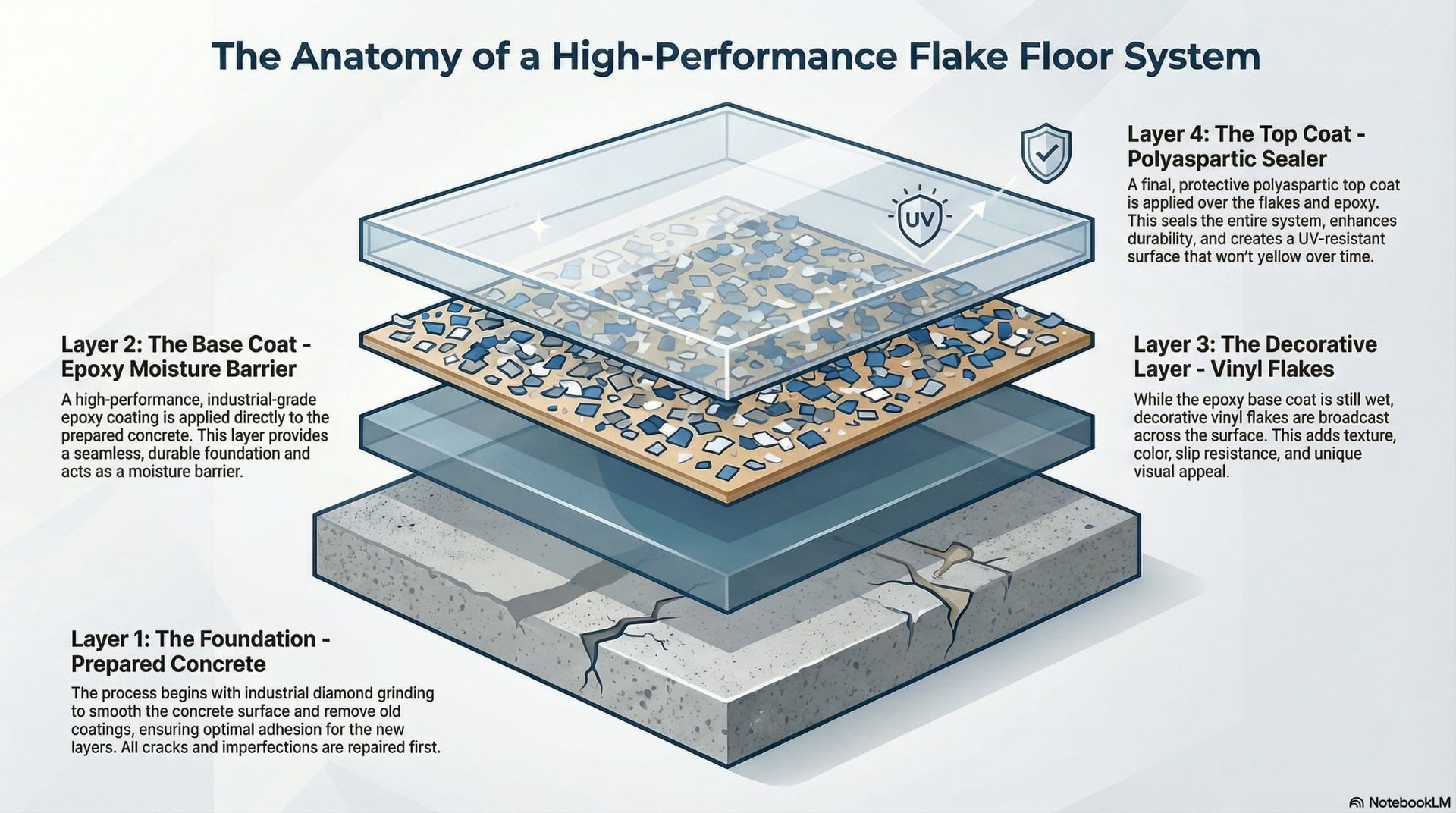

Epoxy flooring is a system, not just a product. The price reflects the labor, materials, and preparation required to ensure proper bonding and long-term performance. Lower prices usually mean steps are skipped, materials are downgraded, or surface prep is rushed, all of which lead to early failure.

A properly installed epoxy floor costs more upfront because it is designed to last longer and require fewer repairs.

Square Footage and Layout Complexity

Total square footage is the starting point for epoxy pricing, but layout complexity plays an equally important role. Open, unobstructed spaces are faster to coat than areas with tight corners, floor drains, equipment bases, or multiple transitions.

Factors that affect labor time include:

• Irregular room shapes

• Columns, curbs, and built-in fixtures

• Edges, stem walls, and vertical surfaces

• Areas requiring hand work instead of machine application

More detailed spaces require more labor, which directly impacts price.

Concrete Condition and Surface Preparation

Surface preparation is one of the biggest cost variables in epoxy flooring. Epoxy will only perform as well as the surface beneath it. Concrete that is cracked, uneven, contaminated, or previously coated requires additional work before epoxy can be applied.

Preparation costs increase when:

• Old coatings or adhesives must be removed

• Oil or chemical contamination is present

• Cracks and joints need repair

• Concrete requires leveling or patching

NES Flooring uses mechanical grinding, not shortcuts, because proper prep is non-negotiable for epoxy longevity.

Moisture Issues and Vapor Mitigation

Concrete naturally holds moisture, and in some buildings, vapor pressure can cause epoxy failure if not addressed. Moisture testing may reveal the need for a vapor barrier or moisture-mitigating primer.

Moisture-related factors include:

• Slab age and condition

• History of water intrusion

• High moisture vapor emission rates

Adding moisture mitigation increases upfront cost but prevents peeling, bubbling, and costly reinstallation later.

Type of Epoxy System Selected

Not all epoxy systems are the same. Material selection has a direct impact on cost and performance. Basic epoxy systems are more affordable, while higher-performance systems designed for heavy use cost more.

Pricing is influenced by:

• Solids content of the epoxy

• Thickness of the system

• Number of coats required

• Use of primers and topcoats

NES Flooring focuses on functional, durable epoxy systems suited for commercial, industrial, and working environments, not decorative upgrades that add cost without improving performance.

Traffic Level and Intended Use

How the floor will be used determines how strong the epoxy system needs to be. A light-duty storage area does not require the same build as a warehouse or service bay with forklifts and heavy equipment.

Higher-use spaces often require:

• Thicker epoxy applications

• Reinforced wear layers

• Slip-resistant additives

• Extended cure times

These upgrades increase cost but are necessary to avoid premature wear.

Downtime and Scheduling Requirements

Project scheduling can also affect pricing. Some facilities require work to be completed during nights, weekends, or tight shutdown windows to minimize disruption.

Scheduling considerations include:

• Off-hours labor

• Accelerated cure products

• Phased installations

Meeting strict timelines requires additional planning and resources, which can influence the final price.

Repairs Versus Full System Installation

In some cases, partial repairs or spot coatings may seem less expensive, but they often fail faster than full system installations. NES Flooring evaluates whether repairs are a cost-effective solution or if a complete system will provide better long-term value.

Short-term savings often lead to higher long-term costs when epoxy is not installed as a complete, properly bonded system.

Maintenance Expectations and Lifecycle Cost

The true cost of epoxy flooring should be evaluated over its lifespan, not just installation day. Higher-quality systems with proper prep last longer, resist chemicals better, and require less maintenance.

When lifecycle cost is considered:

• Fewer repairs are needed

• Downtime is reduced

• Total cost over time is lower

NES Flooring helps clients choose systems that balance upfront cost with long-term durability.

Who Benefits Most From Investing in the Right Epoxy System

Professional epoxy flooring is ideal for:

• Warehouses and distribution centers

• Auto shops and service facilities

• Manufacturing and fabrication spaces

• Commercial and industrial properties

In these environments, cutting corners on flooring leads to operational problems and repeat expenses.

Why Accurate Pricing Requires an On-Site Evaluation

Epoxy flooring cannot be priced accurately without seeing the concrete, understanding the use case, and evaluating site conditions. Estimates based solely on square footage rarely reflect what the project actually requires.

NES Flooring provides straightforward evaluations and clear pricing so clients know exactly what they are paying for and why.

Why Businesses Choose NES Flooring

NES Flooring delivers epoxy flooring built for durability, safety, and real-world performance. With a focus on proper preparation, honest system selection, and reliable installation, clients get floors that justify their cost over time.

Schedule an Epoxy Flooring Cost Evaluation

If you are considering epoxy flooring, understanding the real cost factors is the first step. Contact NES Flooring today to schedule a professional evaluation and receive pricing based on your space, your needs, and long-term performance.

Ready to work with NES Flooring?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 817-668-5051