The Anatomy of a High Performance Flake Floor System

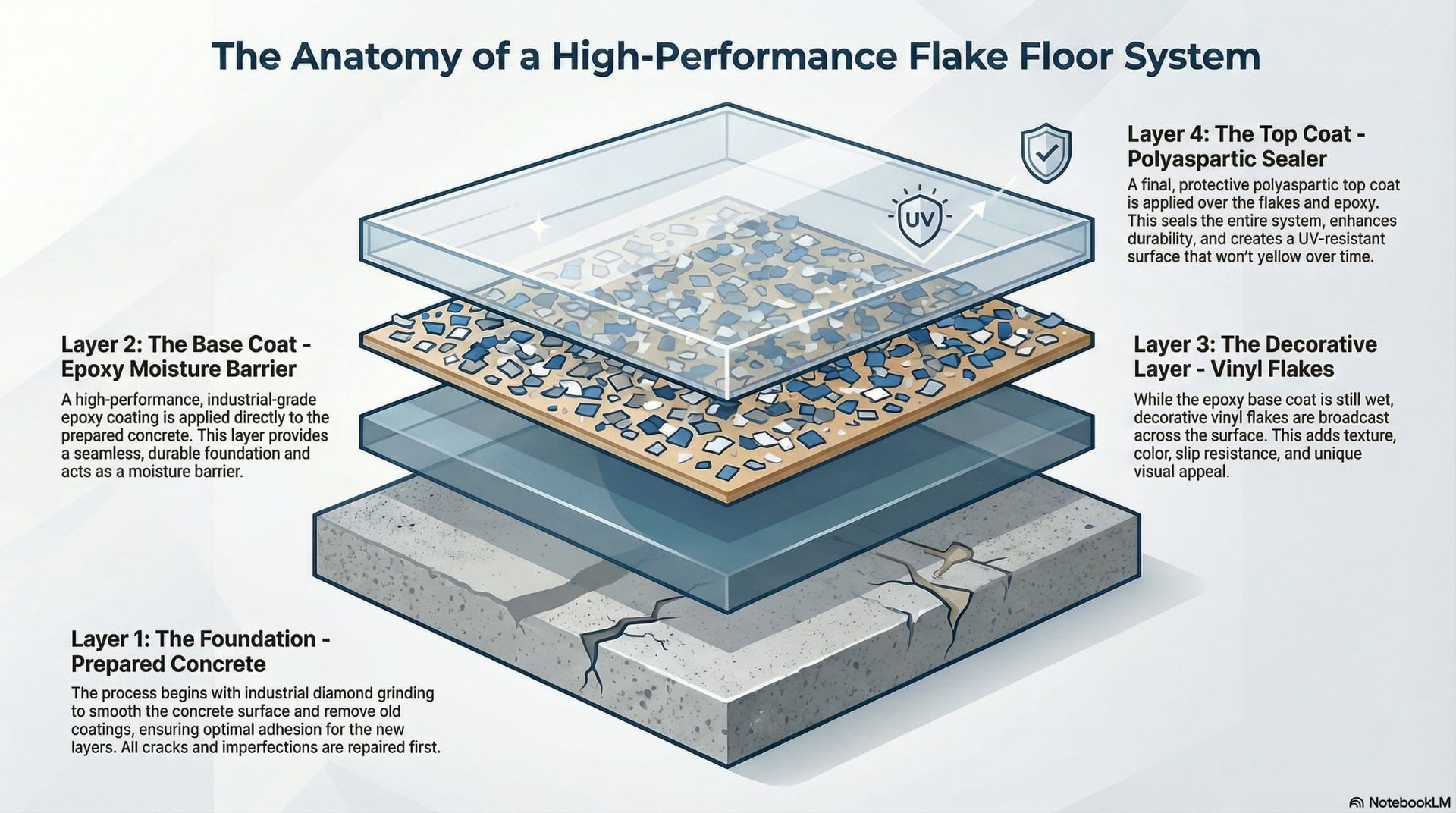

A high performance flake floor system is more than a decorative surface. It is a multi layer flooring build designed to protect concrete, withstand daily wear, and deliver long term durability in demanding environments. When installed correctly, this type of system creates a seamless, moisture resistant, and slip resistant floor that performs far beyond basic coatings or paint.

For commercial spaces, warehouses, garages, and working facilities across Texas, understanding how each layer functions helps explain why professionally installed flake floors last longer, maintain their appearance, and reduce maintenance costs over time.

Why High Performance Flake Floors Rely on a Layered System

Concrete is porous, inconsistent, and constantly affected by moisture movement, temperature swings, and physical stress. A single coat solution cannot manage all of these conditions. A true high performance flake floor is built as a system, with each layer engineered to address a specific challenge.

Together, these layers form a floor that resists moisture intrusion, bonds tightly to the slab, improves traction, absorbs impact, and seals the surface under a durable protective top coat. Skipping steps or using low quality materials weakens the entire system, which is why proper installation is critical.

Layer One - Properly Prepared Concrete Surface

Every successful flake floor begins with thorough concrete preparation. This step is the foundation of long term performance and the most common point of failure when corners are cut.

The concrete surface is mechanically ground to remove contaminants, old coatings, curing compounds, and weak surface material. This process opens the concrete pores and creates the correct surface profile for strong adhesion. Cracks, chips, and surface imperfections are repaired before any coatings are applied.

Without proper preparation, even premium materials can peel or delaminate. Mechanical grinding ensures the base coat permanently bonds to the slab instead of sitting on top of it.

Layer Two - Epoxy Base Coat and Moisture Control Layer

Once the surface is prepared, an epoxy base coat is applied directly to the concrete. This layer acts as the bonding layer and provides moisture control within the system.

High quality epoxy penetrates into the concrete, creating a seamless bond that resists peeling, lifting, and separation. In many Texas facilities, this layer also helps manage moisture vapor rising through the slab, which is one of the most common causes of coating failure.

The epoxy base coat delivers structural strength, chemical resistance, and a solid foundation that supports the decorative layer above it.

Layer Three - Decorative Vinyl Flake Broadcast

While the epoxy base coat is still wet, vinyl flakes are broadcast across the entire surface. These flakes are not just for appearance. They play a functional role in the performance of the floor.

Vinyl flakes add texture that improves slip resistance, help hide small surface imperfections, and create a consistent finish that masks dirt and wear patterns. A full broadcast application, where flakes are applied until the surface will not accept more, ensures even coverage and a more durable finished floor.

After curing, excess flakes are scraped and removed, leaving a textured surface ready to be sealed.

Layer Four - Polyaspartic Protective Top Coat

The final layer is a clear polyaspartic top coat that seals and protects the entire system. This layer is what locks in durability and long term performance.

Polyaspartic coatings offer excellent resistance to abrasion, chemicals, and UV exposure. Unlike lower grade sealers, a quality polyaspartic top coat resists yellowing, staining, and hot tire pickup. It also provides a smooth, easy to clean surface while maintaining traction.

This top coat shields the epoxy and flakes beneath it, helping the floor maintain its appearance and performance under heavy use.

Problems That Occur When Steps Are Skipped

Most flake floor failures can be traced back to shortcuts or improper materials.

Common problems include:

• Peeling or delamination caused by inadequate surface preparation

• Bubbling or blistering from unmanaged moisture vapor

• Rapid wear due to thin or low quality top coats

• Discoloration from UV unstable sealers

• Slippery conditions from improper texture control

A properly built high performance system avoids these issues by treating the floor as a complete system rather than a simple coating.

Where High Performance Flake Floors Work Best

Flake floor systems are well suited for spaces that require durability, safety, and easy maintenance, including:

• Commercial facilities

• Warehouses and distribution spaces

• Automotive shops and service areas

• Garages and equipment rooms

• Retail back of house areas

Their seamless design limits dirt buildup, while their strength allows them to handle vehicles, equipment, and high foot traffic.

What Professional Installation Looks Like in Practice

Professional installation involves more than applying products. It includes evaluating slab conditions, addressing moisture concerns, selecting the right materials, and applying each layer under the proper conditions.

Experienced installers understand how temperature and humidity affect cure times and performance. They also adjust system details based on how the space will be used, whether that means added slip resistance, enhanced chemical protection, or faster return to service.

This level of attention is what separates long lasting floors from short term solutions.

How to Protect Your Flake Floor Investment

To get the most value from a flake floor system:

• Start with proper concrete evaluation and preparation

• Use high quality epoxy and polyaspartic materials

• Ensure full broadcast flake coverage

• Apply a durable, UV stable top coat

• Work with a flooring contractor experienced in performance driven systems

A flake floor is an investment in safety, durability, and long term cost control.

Why NES Flooring Focuses on Performance First

NES Flooring delivers straightforward flooring solutions built for real world Texas conditions. Every flake floor system is installed with proper preparation, proven materials, and a process designed for longevity rather than shortcuts.

The focus is on floors that perform under pressure, remain easy to maintain, and continue delivering value year after year.

Schedule a Flake Floor Consultation with NES Flooring

If you are considering a high performance flake floor for your facility, NES Flooring can help you determine the right system for your space.

Contact NES Flooring today to schedule a consultation and get a floor built to perform from the slab up.

Ready to work with NES Flooring?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 817-668-5051