Epoxy Flooring for Garages and Shops - Premium Protection That Works as Hard as You Do

Epoxy flooring is one of the most durable and cost-effective upgrades you can make to a garage or shop. For homeowners and business owners across Texas, epoxy delivers a seamless, chemical-resistant surface that stands up to heavy vehicles, tools, and daily abuse while keeping the space clean and professional-looking.

When installed correctly, epoxy flooring is not just a coating. It is a long-term protective system designed to shield concrete from wear, moisture intrusion, and staining, especially in high-use environments like garages, workshops, and light industrial spaces.

Why Epoxy Flooring Matters in Texas Garages and Workspaces

Concrete may look solid, but it is naturally porous. Oil drips, brake fluid, moisture, and chemicals soak in quickly, leading to stains, surface breakdown, and dusting over time. In Texas, garages and shops also face extreme temperature swings, high humidity in some regions, and tracked-in dirt that accelerates concrete wear.

Epoxy flooring creates a sealed, non-porous surface that protects the slab underneath. It prevents absorption, strengthens the surface, and makes cleanup simple. Instead of fighting concrete deterioration, epoxy turns your floor into a functional asset that supports how the space is actually used.

Key Benefits of Professional Epoxy Flooring Systems

•

Long-lasting protection against oil, chemicals, and tire marks

• Seamless surface that will not trap dirt or dust

• Improved light reflection for safer, brighter work areas

• Increased resistance to moisture and surface cracking

• Clean, finished appearance that elevates the entire space

For shops and garages that see real use, epoxy flooring offers both performance and visual improvement without constant maintenance.

Common Problems with DIY or Low-Quality Epoxy Floors

Many epoxy floor failures are not caused by the product itself, but by improper preparation and shortcuts during installation. Hardware-store kits and inexperienced installers often skip critical steps, leading to peeling, bubbling, or premature wear.

Common issues include:

• Poor concrete grinding or acid etching

• Moisture trapped beneath the coating

• Thin epoxy layers that wear through quickly

• Hot tire pickup from inferior materials

• Uneven texture or visible roller marks

Once epoxy fails, repairs are rarely simple. Most failed floors must be completely ground down and redone. Professional installation prevents these problems from the start.

Who Epoxy Flooring Is Best Suited For

Epoxy flooring is ideal for anyone who needs a tough, low-maintenance surface that can handle repeated use without breaking down.

This includes:

• Residential garages with daily vehicle traffic

• Automotive and mechanical shops

• Warehouses and storage facilities

• Home workshops and hobby spaces

• Commercial service bays and equipment rooms

If the floor needs to handle weight, spills, and movement while staying clean and presentable, epoxy is a smart choice.

How Epoxy Performs in Texas Conditions

Heat and humidity are major factors in flooring performance. Epoxy systems used in Texas must be installed with proper moisture testing and climate-aware curing methods. When done correctly, epoxy handles hot summers and seasonal changes without delaminating or softening.

Professional-grade epoxy systems are designed to bond deep into the concrete, not just sit on top. This creates a surface that stays stable even when temperatures fluctuate or vehicles bring in heat from the road.

What Professional Epoxy Installation Looks Like

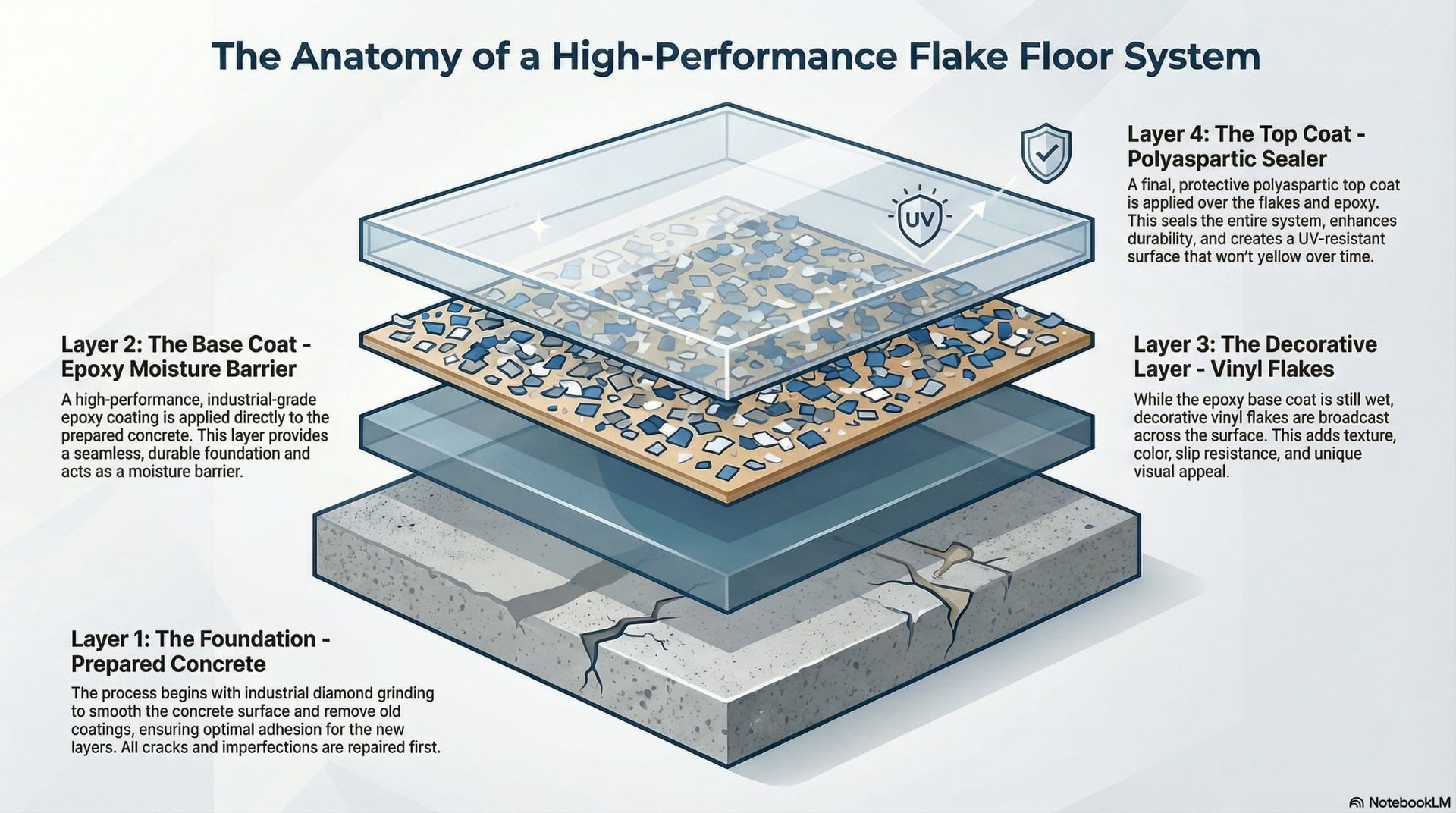

A true epoxy flooring system starts long before the coating is applied. The most important step is surface preparation. Concrete is mechanically ground to remove contaminants and open the pores of the slab. This creates the profile needed for epoxy to bond correctly.

After preparation, installers address cracks, joints, and moisture concerns. The epoxy system is then applied in multiple layers, which may include a base coat, decorative elements if desired, and a protective topcoat designed for durability and traction.

This process ensures the floor cures evenly, bonds properly, and performs as intended for years.

Simple Maintenance That Saves Time and Money

Epoxy floors are easy to maintain compared to bare concrete. Routine sweeping and occasional mopping keep the surface clean. Spills wipe up quickly without leaving stains, and the sealed surface prevents dust from forming.

For busy garages and shops, this means less downtime, fewer repairs, and a cleaner workspace overall.

Actionable Steps Before Choosing Epoxy Flooring

• Evaluate how the space is used daily

• Consider vehicle weight, chemicals, and traffic patterns

• Avoid one-day coating claims without prep details

• Choose installers who grind concrete, not just clean it

• Ask about moisture testing and warranty coverage

The right epoxy system should match the demands of the space, not just the budget.

Frequently Asked Questions About Epoxy Flooring

How long does epoxy flooring last?

With proper installation and normal use, epoxy floors can last 10 to 20 years or more in garages and shops.

Will epoxy be slippery?

Professional systems include optional texture additives that improve traction without making the floor difficult to clean.

Can epoxy be installed over old concrete?

Yes, as long as the concrete is structurally sound and properly prepared through grinding and repair.

How long before the floor can be used?

Most epoxy floors can handle foot traffic within 24 hours and vehicle traffic within several days, depending on the system used.

Why Choose NES Flooring for Epoxy Flooring

NES Flooring focuses on durable, no-nonsense flooring solutions built for real-world use. Every epoxy installation is completed with proper surface preparation, professional materials, and attention to long-term performance. The goal is not just a good-looking floor, but a surface that holds up under pressure year after year.

With experience in high-use environments and a commitment to quality results, NES Flooring delivers epoxy systems that work as hard as Texas garages and shops demand.

Get a Floor That Protects Your Space

If your garage or shop floor is stained, dusty, or breaking down, epoxy flooring offers a proven solution. Contact NES Flooring today to schedule a consultation and get a durable epoxy floor built to last.

Ready to work with NES Flooring?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 817-668-5051