How Epoxy Flooring Delivers Long Lasting Performance in Harsh Texas Heat

Texas heat is relentless, and bare concrete or low quality coatings rarely hold up under extreme temperature swings, direct sun exposure, hot tire contact, and heavy daily use.

Epoxy flooring, when installed with the right materials and prep, provides a dependable barrier that stands strong despite the challenges of our climate. At NES Flooring, we focus on systems engineered specifically for Texas conditions, giving homeowners durable floors that look sharp and perform reliably year after year.

Why Heat Resistant Epoxy Matters for Texas Homes and Workspaces

High temperatures cause concrete to expand, and poor coatings often peel, bubble, or delaminate as a result. Epoxy flooring creates a bonded, protective layer that absorbs thermal stress without lifting or cracking. This stability is essential for garages, workshops, patios, and utility areas where concrete is exposed to summer heat or rapid temperature changes from vehicles and equipment.

How Epoxy Flooring Holds Up Against Extreme Temperatures

Several factors contribute to epoxy's resilience in hot climates, especially when installed correctly:

• Engineered thermal resistance: Quality epoxies are formulated to remain stable under both surface and ambient heat, preventing softening or deformation.

• Strong adhesion after mechanical prep: Grinding opens the concrete and allows the epoxy to anchor deep into the slab, reducing the risk of peeling in hot weather.

• UV stable topcoats: Polyaspartic and urethane finishes defend against discoloration and degradation from sun exposure at garage entries and patios.

• Chemical and tire resistance: High temps amplify oil penetration and hot tire lift on weak coatings, but industrial epoxies resist both challenges.

• Moisture mitigation: Heat can drive moisture up through the slab. Moisture tolerant primers help maintain adhesion even when vapor pressure rises.

Together, these components form a system that withstands heat, humidity fluctuations, and heavy Texas use.

Who Benefits Most From Heat Ready Epoxy Flooring Systems

Epoxy flooring is an excellent upgrade for:

• Homeowners who want a durable garage floor that resists peeling and stains

• Workshop or hobby area users needing a clean, resilient surface

• Small businesses operating in high heat environments or with frequent vehicle traffic

• Property managers looking for low maintenance, long lasting flooring solutions

Anyone dealing with Texas temperature extremes gains added reliability, lower upkeep, and improved safety from a professional epoxy installation.

Texas Climate Factors That Influence Epoxy Performance

Heat is only part of the challenge. Texas conditions introduce a mix of structural and environmental issues that epoxy helps solve:

• Intense UV exposure near garage thresholds

• Hot tire transfer from vehicles driven on scorching pavement

• Dust that settles into porous concrete and accelerates wear

• Occasional humidity shifts that stress unprotected slabs

• Seasonal expansion and contraction that widen cracks

A professionally installed epoxy system protects the concrete from these forces, extending its lifespan and improving daily usability.

What Professional Heat Resistant Epoxy Installation Looks Like

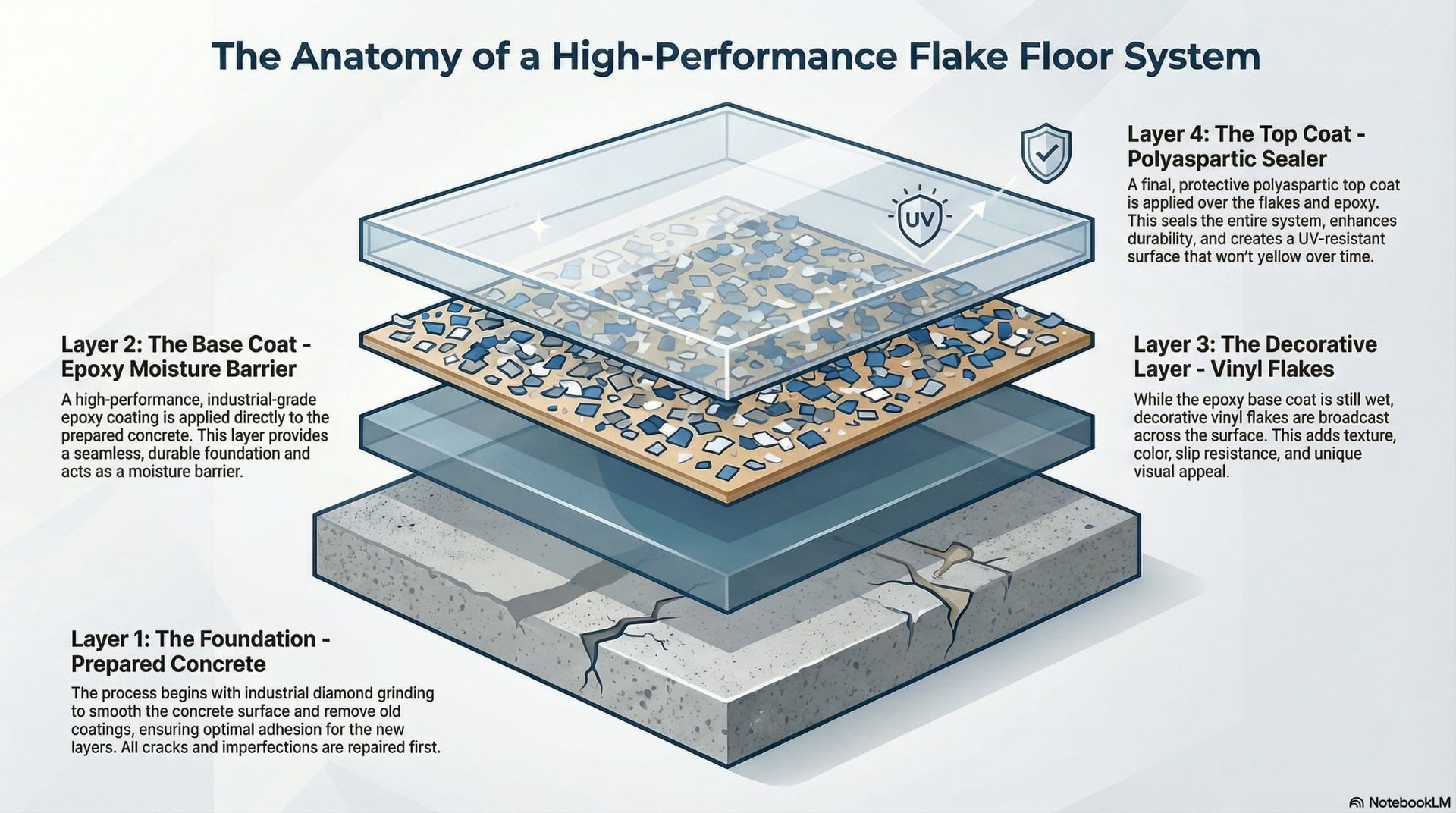

NES Flooring follows a results driven installation process built around proper prep and proven materials:

• Mechanical grinding to open the concrete and remove contaminants

• Moisture testing and vapor mitigation when needed

• Repair of cracks, pitting, or spalling for a smooth final surface

• Application of a high performance epoxy basecoat engineered for Texas heat

• Optional flake broadcast for traction and enhanced aesthetics

• UV stable polyaspartic or urethane topcoat for maximum longevity

Each step is geared toward long term adhesion, color stability, and resistance to heat related stress.

How Homeowners Can Prepare for an Epoxy Flooring Project

Before installation, you can help ensure a smooth project timeline by:

• Clearing all stored items from the garage or workspace

• Noting areas with staining, cracking, or moisture concerns

• Considering preferred finish types, from solid color to full flake systems

• Planning alternate parking or workspace during curing

• Asking about maintenance needs for your chosen topcoat

These simple preparations help us deliver an efficient, clean installation that supports long term performance.

Frequent Questions About Epoxy Flooring in Texas Heat

Will epoxy melt or soften in extreme heat?

High quality epoxies remain stable and rigid even under strong Texas heat when applied correctly.

Can epoxy handle hot tire contact?

Yes. Commercial grade systems with proper concrete prep resist hot tire lift.

Does sun exposure fade epoxy?

Unprotected epoxy can yellow over time, which is why we apply UV stable topcoats to prevent discoloration.

Is epoxy cooler than bare concrete?

Epoxy does not trap as much heat as untreated slab and generally feels more comfortable to walk on.

Why Texas Homeowners Trust NES Flooring for Heat Resistant Epoxy Solutions

NES Flooring focuses on durable results, straightforward recommendations, and installation methods tailored to Texas climate challenges. Our epoxy systems are engineered to withstand heat, resist wear, and protect your concrete for years to come. We take pride in delivering floors that look clean, perform reliably, and hold up under real world Texas temperatures.

When you are ready for an epoxy floor built to stand up to Texas heat, contact NES Flooring for a professional consultation and detailed quote.

Ready to work with NES Flooring?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 817-668-5051